Hot in-place recycling is a low-waste technology that significantly reduces the need for raw materials during the reconstruction of surface and binder layers of roads.

Hot in-place recycling is a low-waste technology that significantly reduces the need for raw materials during the reconstruction of surface and binder layers of roads.

This advanced method reshapes and improves the quality of the existing asphalt layer, and within the same work cycle, it allows the simultaneous application of a new wearing course (REMIX PLUS).

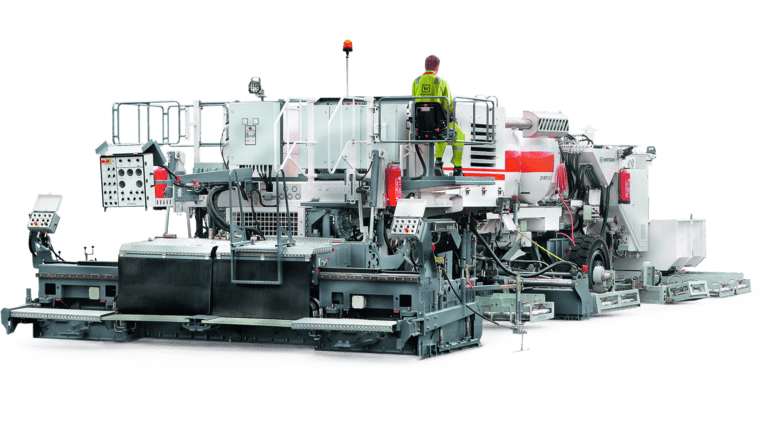

The hot in-place recycling train consists of preheaters that gradually heat the asphalt layer to the required temperature using propane-butane infrared heaters. The core of the system is the remixer, which breaks up the heated layer using a milling drum and thoroughly mixes the reclaimed material with any added components (asphalt binder, aggregates, or asphalt mix).

The final section of the remixer includes two independently heated screeds that spread, shape, and pre-compact the homogenized mixture.

Final compaction of the recycled layer or layered structure is performed using two tandem road rollers.

This technology enables four primary variants of hot in-place asphalt recycling. The most commonly used methods are REMIX and REMIX PLUS, while RESHAPE and REPAVE are used less frequently.

Reshaping of the existing pavement layer through recycling, along with quality enhancement of the asphalt mixture.

Reshaping of the existing pavement layer through recycling, along with quality enhancement of the asphalt mixture.

The original asphalt layer is modified to achieve the desired physical and mechanical properties by adding specific components. The construction of the remixer allows for the incorporation of asphalt binder and asphalt mix according to a predefined mix design.

The REMIX process consists of the following steps:

Reshaping of the pavement surface through recycling, with enhancement of the existing asphalt layer and simultaneous laying of a new wearing course.

With the REMIX PLUS technology, two asphalt layers are laid in a single work cycle. The original pavement layer is modified using the REMIX method by adding necessary components to form the recycled binder layer. On top of this, a new “plus” wearing course is applied immediately in the same pass.

The REMIX PLUS process includes the following steps:

Longitudinal cracks and open construction joints are a common issue on roads, typically appearing at the connections between traffic lanes. If these defects are not repaired in time, the wearing course gradually degrades, leading to potholes and reduced pavement lifespan.

For repairing longitudinal and construction joints, a remixer with a fixed working width of 300 mm, 500 mm, 600 mm, or 1000 mm is used, depending on the defect width and equipment. In hot in-place recycling, the pavement is preheated to a depth of 60–70 mm using the remixer’s infrared burners, while the recycling itself takes place at a depth of 30–40 mm.

The surface is heated with propane-butane infrared heaters. Once heated, the asphalt layer is loosened by the remixer and enriched with asphalt emulsion and new hot-mixed asphalt. Since the layer is only broken after it has been sufficiently heated, aggregate particles remain intact—unlike in conventional cold milling—so there is no need to adjust the gradation by adding fresh aggregate.

The modified mixture is then laid back and pre-compacted by the remixer’s screed. Final compaction is performed using a tandem roller.